The Hayes Valley MEP Coordination

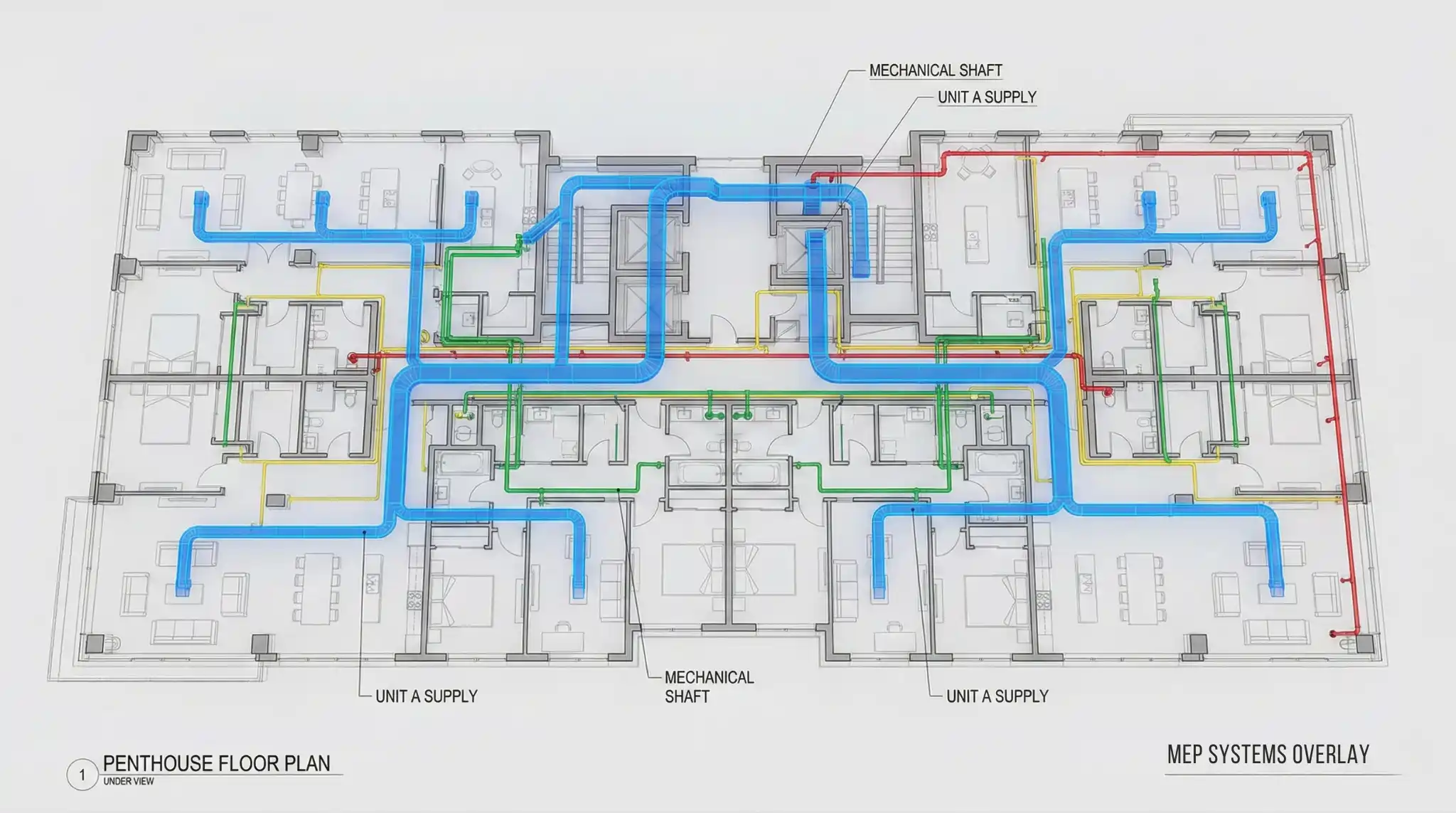

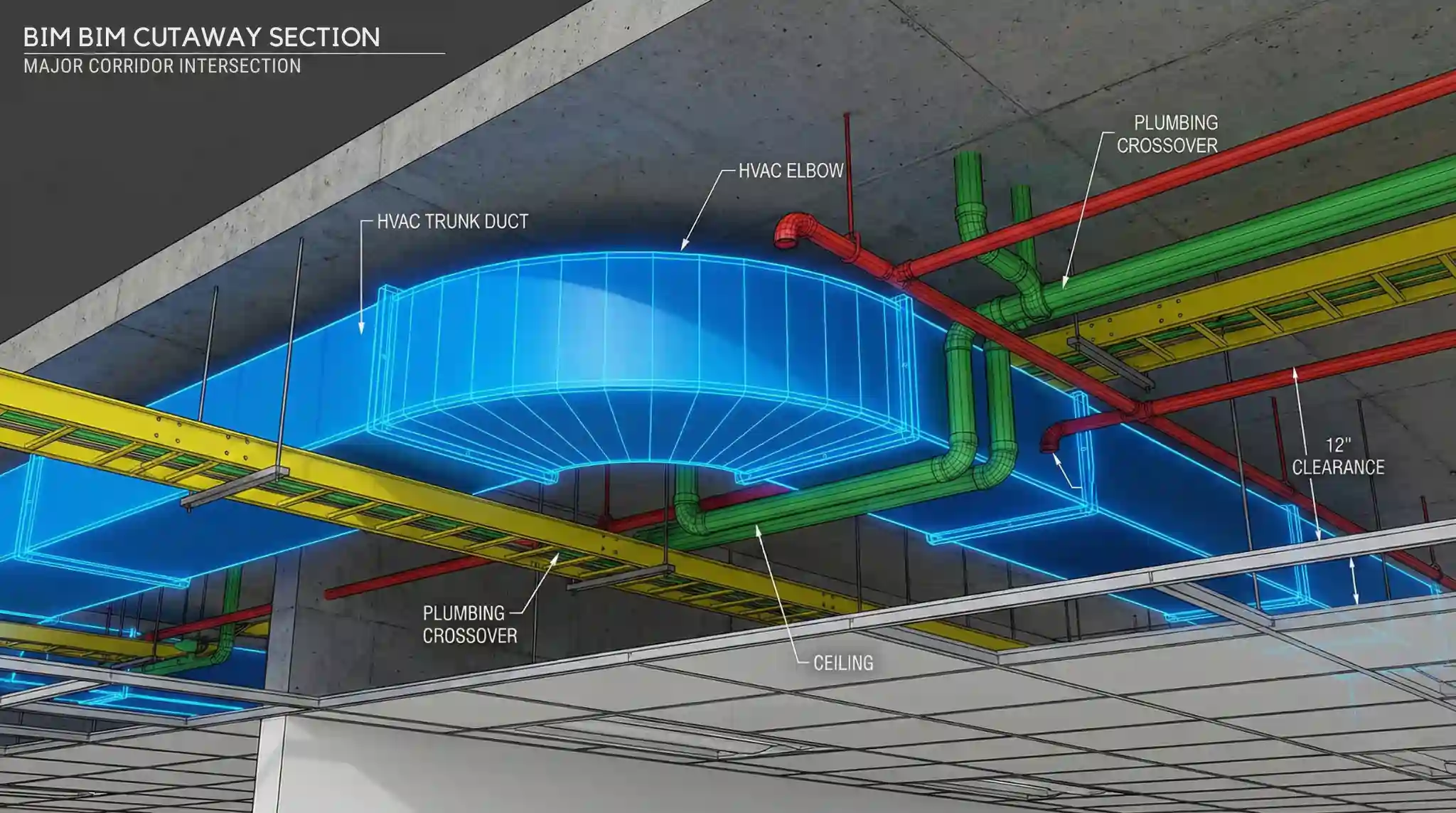

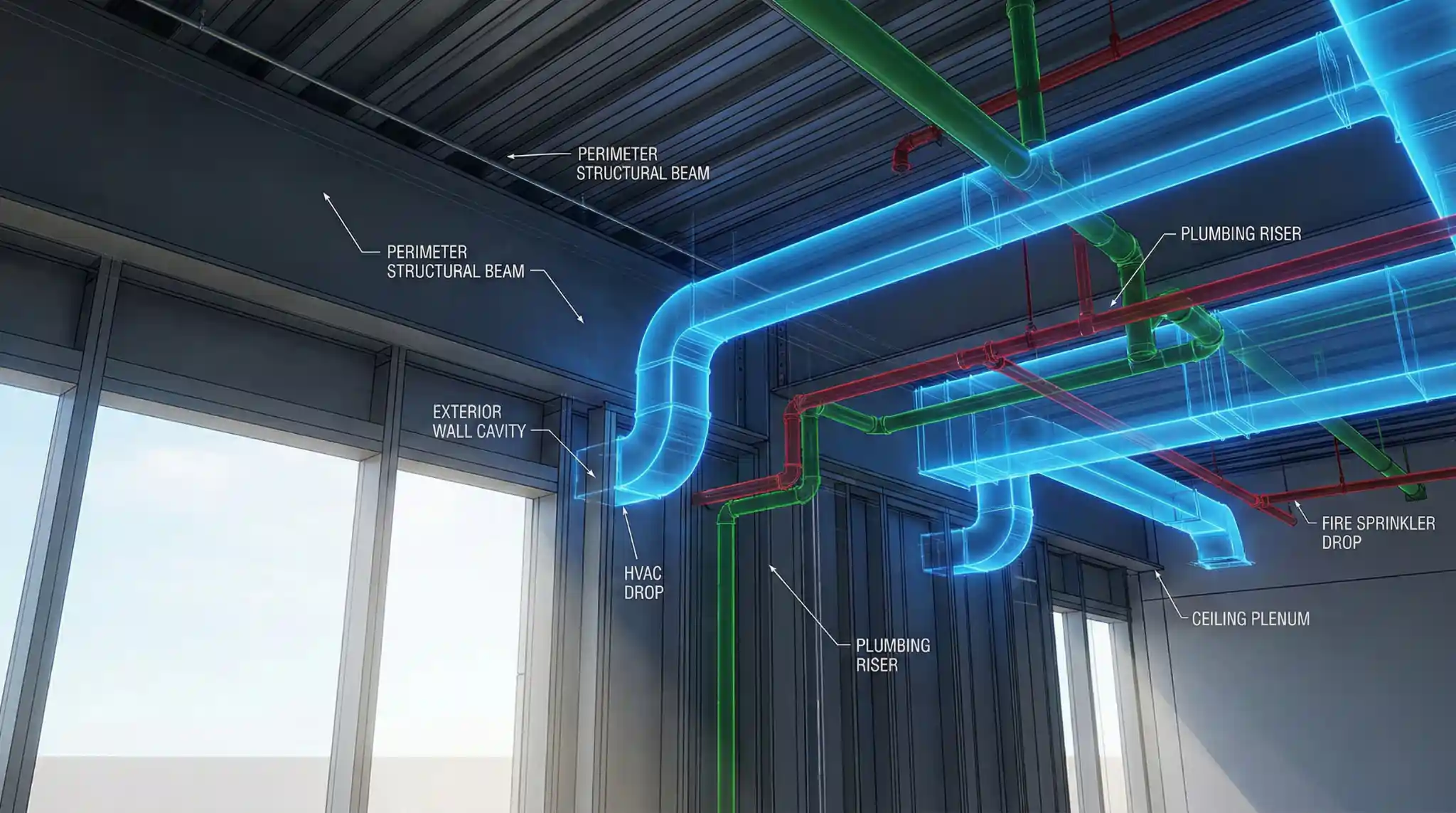

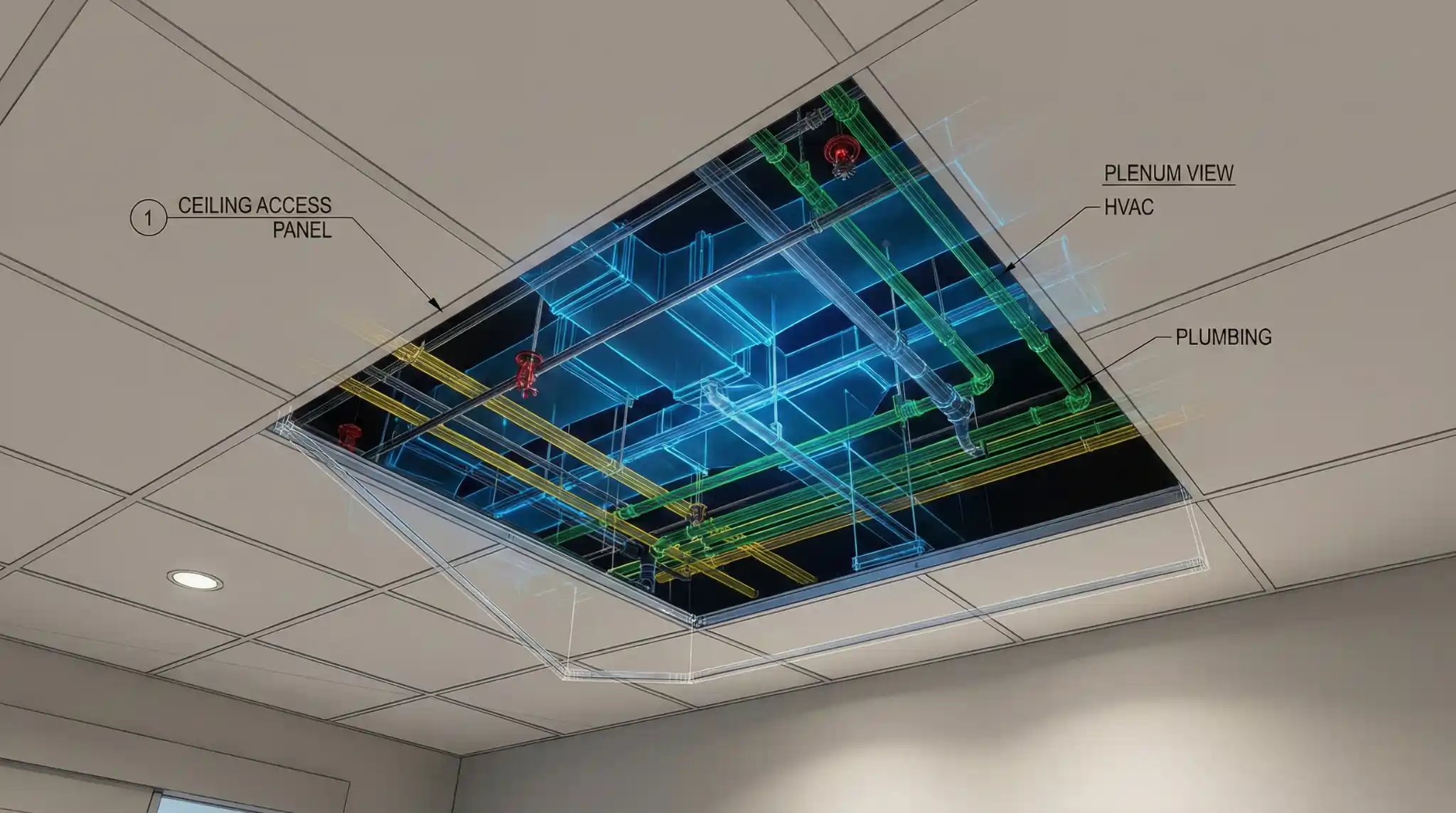

In a luxury mixed-use building in Hayes Valley, ceiling height is money. The developer wanted to maximize the ceiling heights in the penthouse units, leaving only 12 inches of plenum space above the ceiling for all the mechanical, electrical, and plumbing systems. The plumber, electrician, and HVAC installer were all arguing, claiming there was not enough room for their equipment. They were heading towards a field conflict where pipes would have to be routed below the ceiling, ruining the clean aesthetic the architect designed.

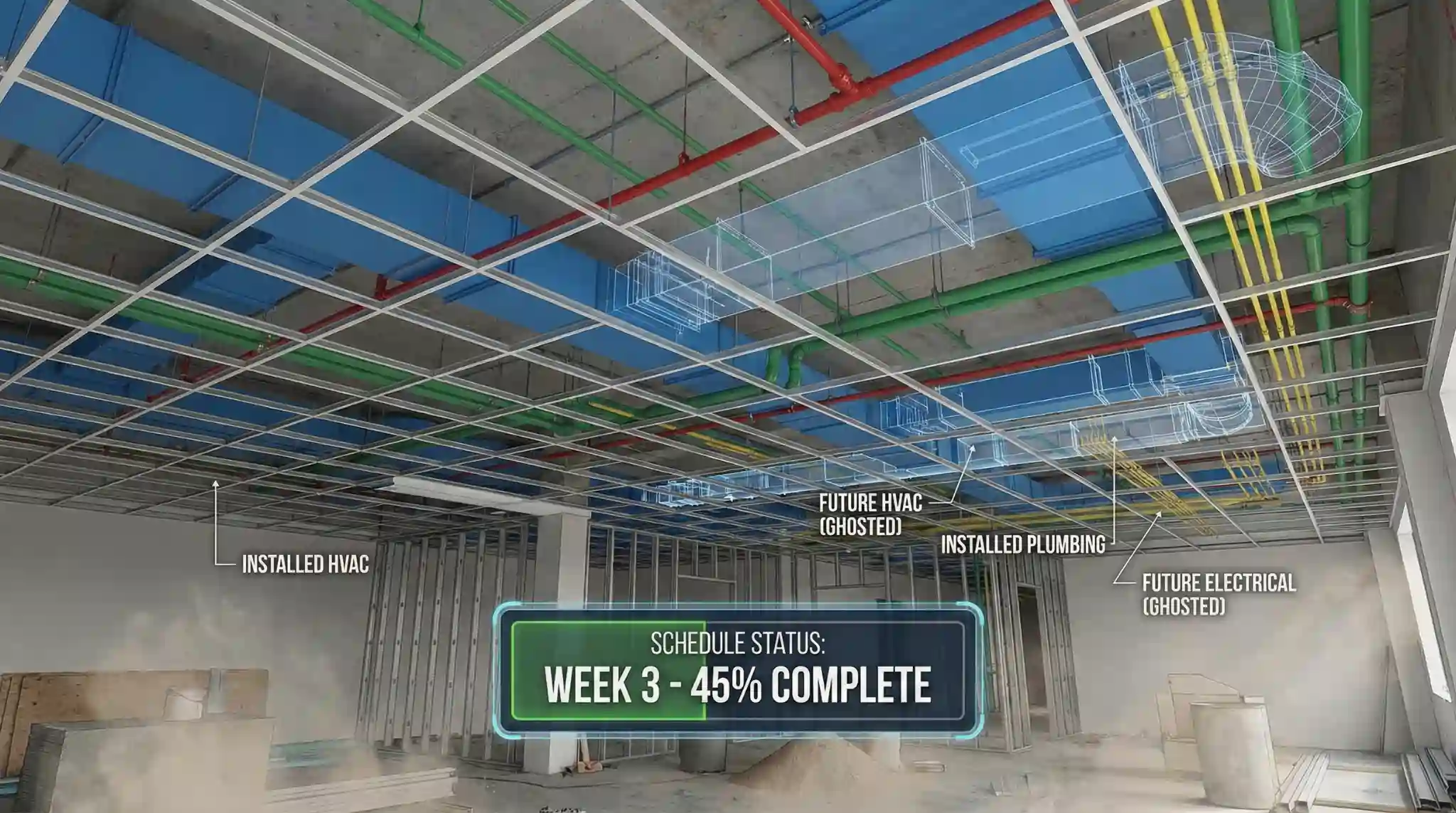

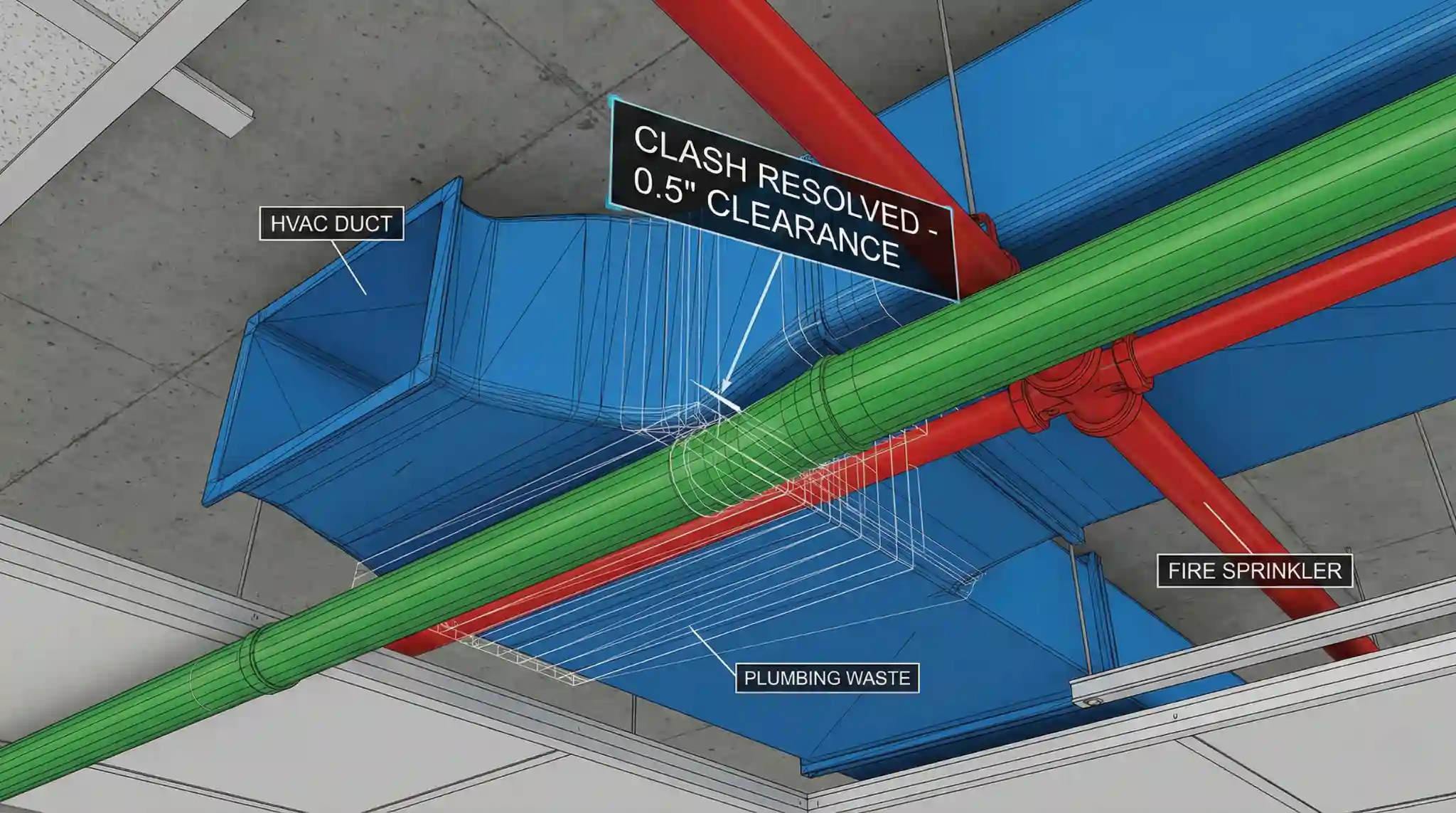

We took on the role of the 3D Coordinator. Using models provided by the subcontractors, we integrated every single duct, pipe, conduit, and fire sprinkler head in 3D. We ran automated clash detection reports which identified 45 distinct areas where the HVAC ducts were hitting the plumbing waste lines. We did not just report the problems; we modeled solutions. We re-routed the ductwork in the 3D model, flattening the profiles in tight areas and threading the fire sprinklers through the gaps. We proved that all systems could fit within the tight 12-inch ceiling cavity, saving the design intent.

Client Name

Vantage Builders

Client Type

General Contractor

Location

Hayes Valley, San Francisco

Project focus

MEP clash detection and coordination

Color Palette

HVAC Blue, Plumbing Green, Electrical Yellow, Fire Red

Services Provided

3D Modeling, Clash Detection, Systems Coordination

Budget

$2,000

Duration

5 Weeks

Thoughtfully designed spaces for life

Strategic Design Interventions

We use intelligent 3D data to eliminate construction risk.

1

Automated Conflict Resolution

A human eye can miss a pipe hitting a beam on a 2D drawing. Our clash detection software never misses. We identified a critical conflict where the main sewer line intersected with a structural steel beam. Catching this in the model saved the project a $15,000 beam penetration fix.

Prefabrication Enablement

Because our piping model was so accurate, the plumber was able to pre-cut and assemble the copper piping off-site. They simply brought the spools to the job site and bolted them together, cutting their installation time in half.

2

3

Maintenance Access Planning

We did not just model the equipment; we modeled the empty space needed to service it. We ensured that every filter and valve had the required clearance in the 3D model, ensuring the building maintenance team would not be cursing the design five years from now.

Want to know more?

Address

-

1875 Mission St Ste 103 #628 San Francisco, CA 94103

Hours

-

Mon–Fri 9:00AM — 6:00PM

Socials

Send us a message