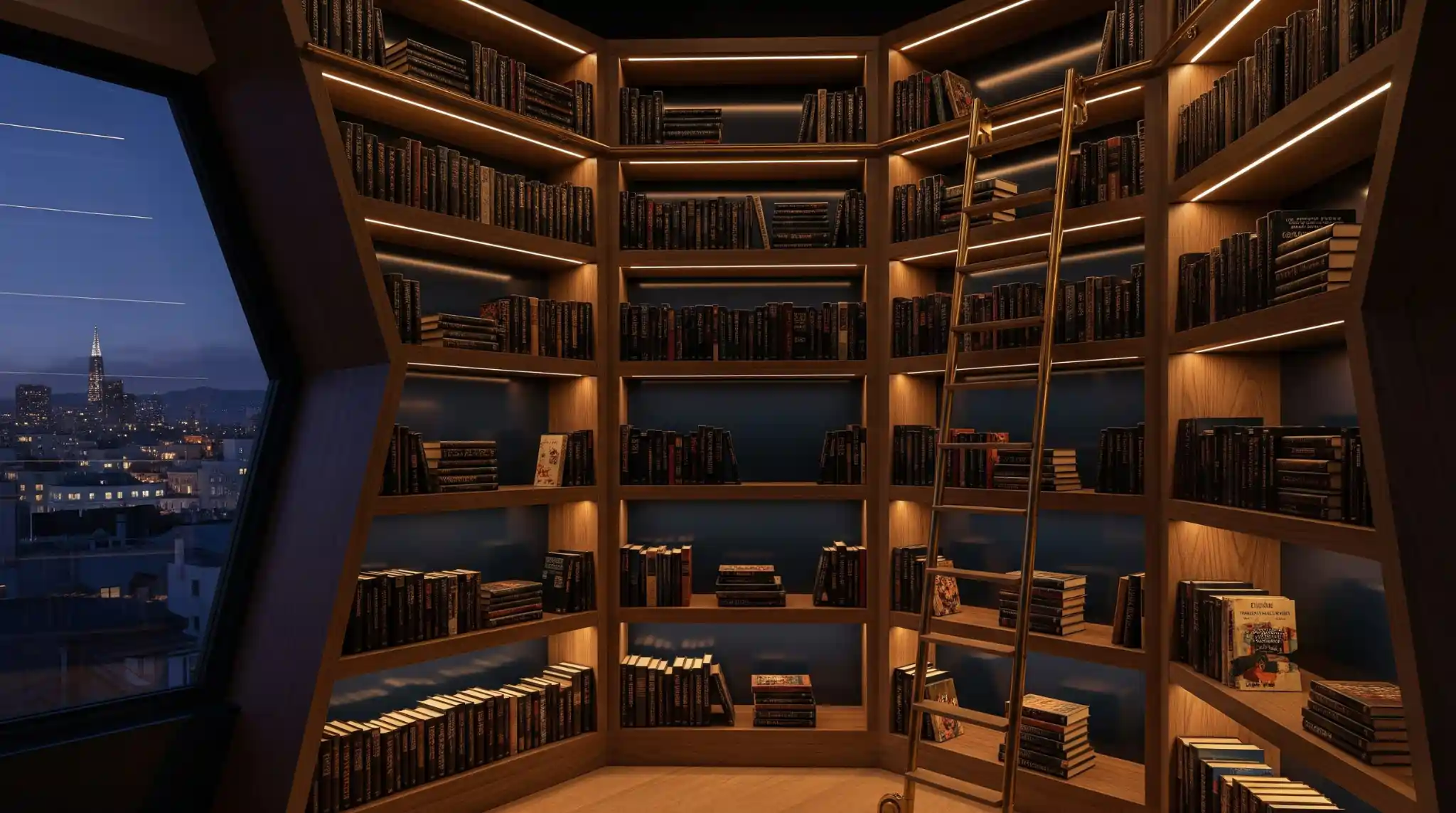

The Impossible Russian Hill Library

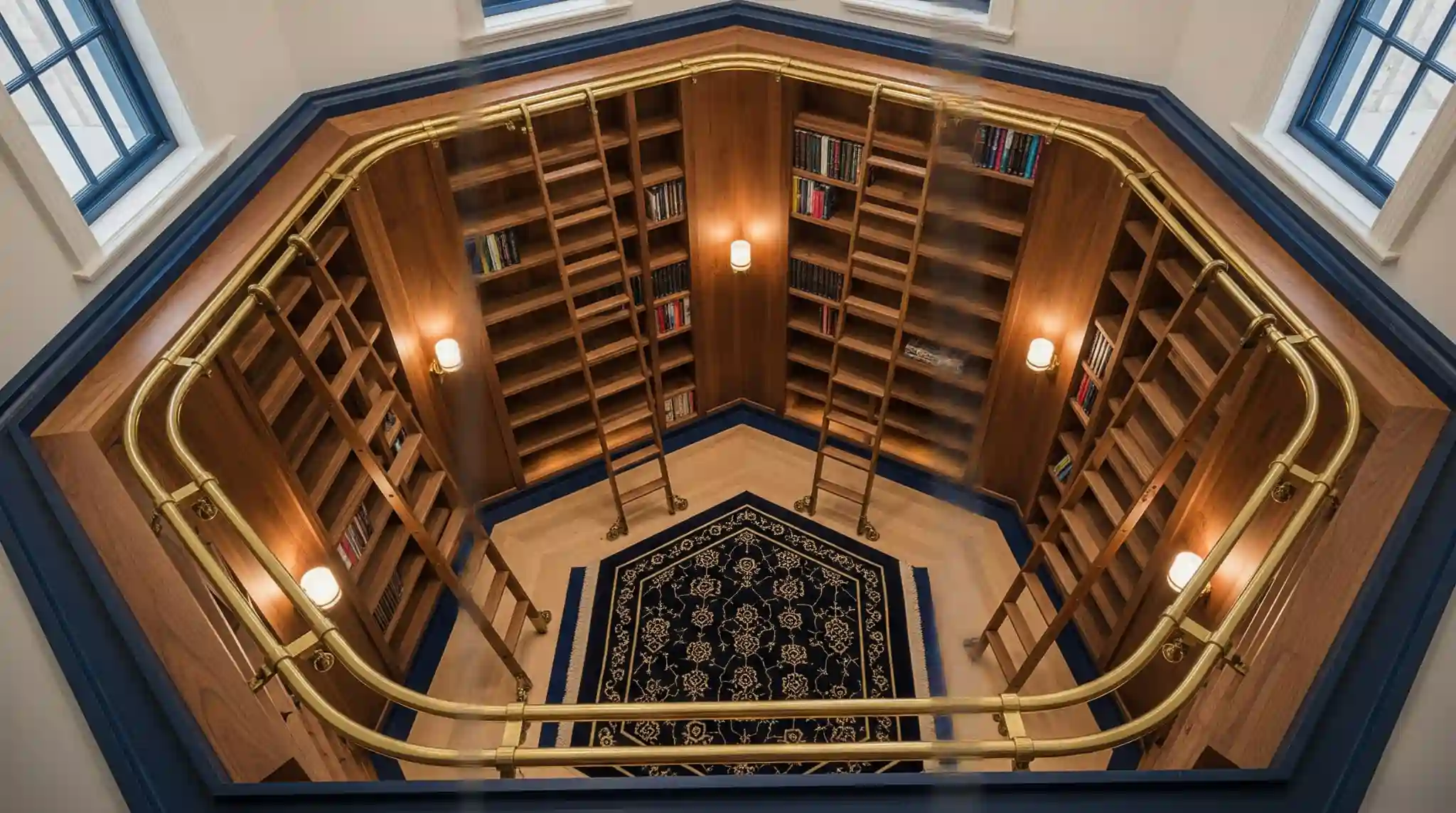

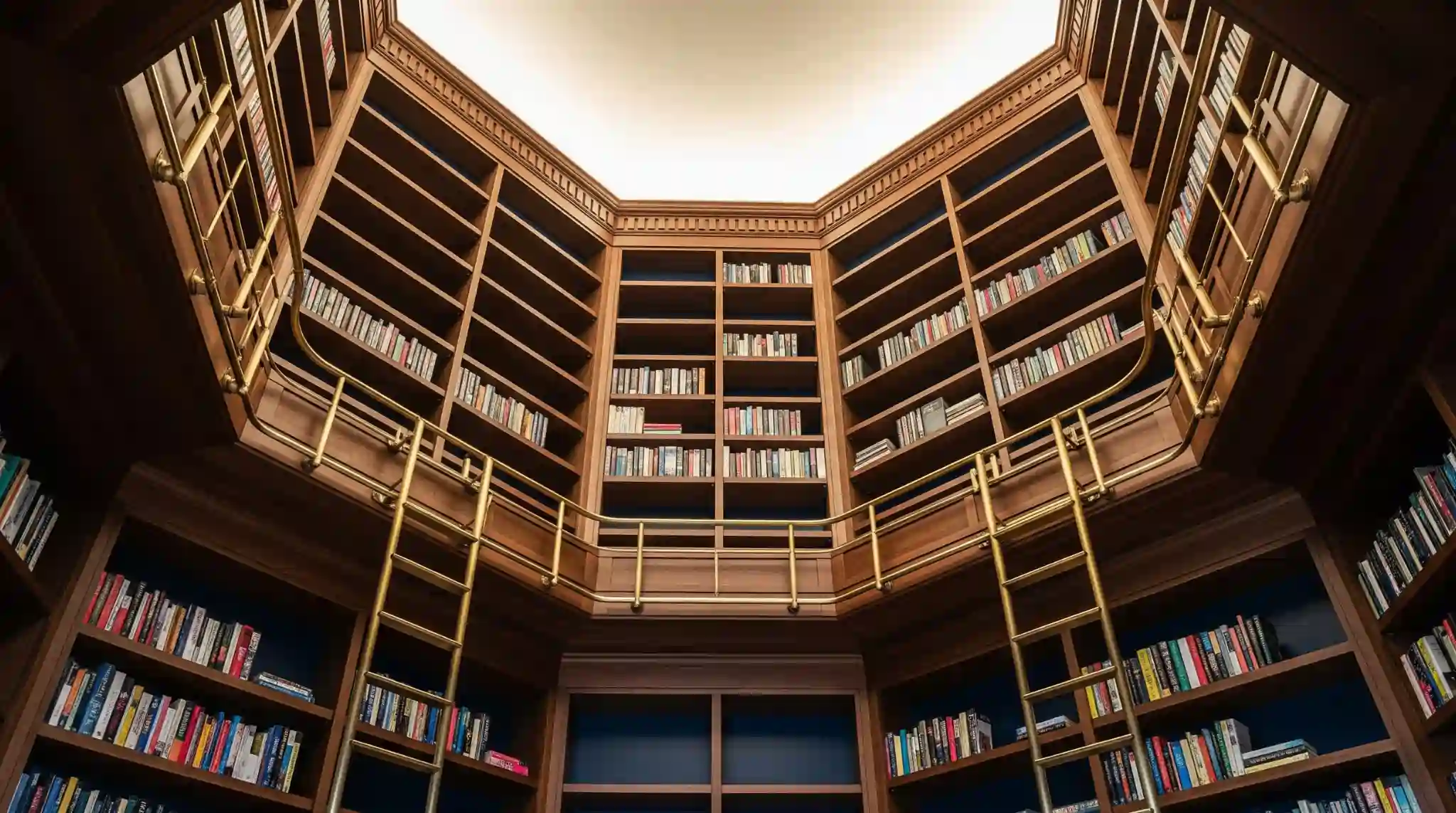

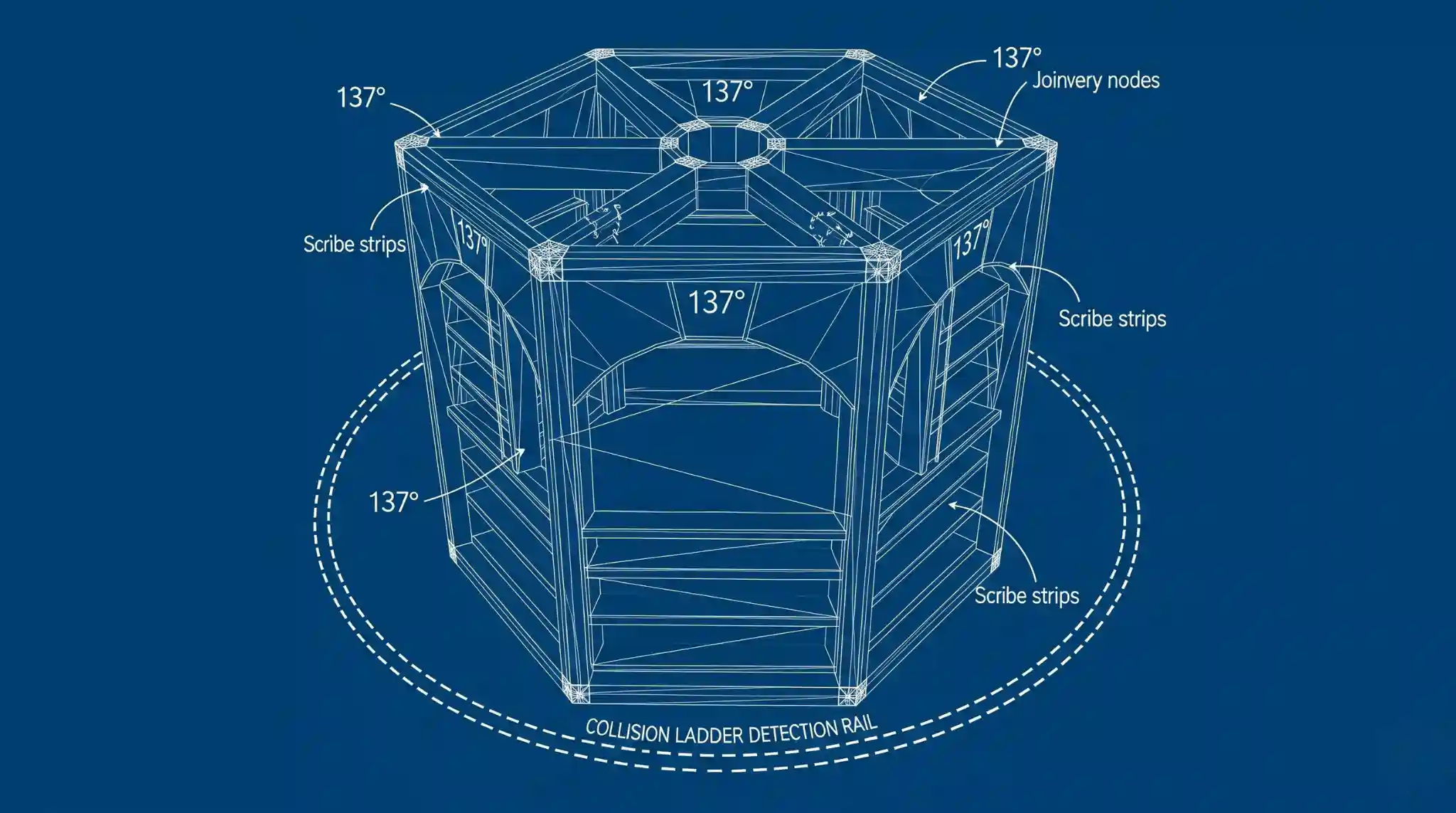

Russian Hill homes are famous for their views but notorious for their bizarre geometry. Our client had a hexagonal turret room with non-standard angles, not 90 degrees, not 45 degrees, but a headache-inducing 137 degrees. They wanted a floor-to-ceiling library with a rolling ladder and integrated seating. Three previous carpenters had walked away from the job because standard 2D elevations could not accurately capture the complex intersection of the coved ceiling and the angular walls. The client needed a solution that looked original to the 1920s architecture but functioned with modern precision.

We did not sketch this; we sculpted it. Using the digital scan data provided by the client, we designed the entire library system in 3D CAD software, modeling every shelf, join, and molding profile. This allowed us to virtually test the rolling ladder path to ensure it would not hit the chandelier or the window casings, a clash we discovered and fixed digitally. We exported the 3D files directly to a local millworker who CNC-machined the components. The installation took 2 days instead of the projected 2 weeks because the parts fit like a Lego set.

Client Name

The Sterling Estate

Client Type

Private Homeowner

Location

Russian Hill, San Francisco

Project focus

Complex custom millwork and fabrication

Color Palette

Walnut, Brass, Navy Lacquer, Parchment

Services Provided

3D Design, 3D Scanning, Fabrication Files

Budget

$85,00

Duration

6 Weeks

Thoughtfully designed spaces for life

Strategic Design Interventions

We use 3D geometry to bridge the gap between architectural vision and manufacturing reality

1

The Digital Fit Check

Standard measuring tapes lie, especially in old houses. By 3D modeling the room exact imperfections, we designed scribe strips into the cabinetry. This allowed the installers to trim the edges to match the wavy plaster walls perfectly, creating a built-in look that appears seamless.

Collision Detection

The rolling ladder was a major risk. In our 3D simulation, we realized the ladder rail would block the swing of the original window shutters. We redesigned the rail profile in 3D to create a custom offset, preserving the function of the historic windows while giving the client their dream library.

2

3

CNC-Ready Files

We did not hand the builder drawings; we handed the machine code. By designing the joinery in 3D, we reduced material waste by 20% and eliminated human error in the cutting process. The complex angles were cut by a robot, not a carpenter with a protractor.

Want to know more?

Address

-

1875 Mission St Ste 103 #628 San Francisco, CA 94103

Hours

-

Mon–Fri 9:00AM — 6:00PM

Socials

Send us a message